Summary : There are situations where, midway through a project, clients demand additional work that was not foreseen. Such situations can cause the project to take longer and cost more. To avoid this scenario, electrical workers should clearly explain the entire project scope, maintain written documentation for all changes, prepare personnel to follow procedures, and use digital tools for planning. Clear communication is what keeps a project on schedule and within budget.

Electrical and low-voltage projects have a tendency to expand beyond the initially agreed scope. A single “quick change” can snowball into additional cabling runs, extra outlets, more testing, and reduced profit margins. Scope creep can derail schedules and exhaust resources.

In a report released by the Project Management Institute (PMI) in 2023, 52% of construction projects experienced scope creep during the previous year. According to the Construction Industry Institute (CII), the U.S. construction industry incurs nearly $75 billion annually in rework costs, with around 5% attributed to uncontrolled project changes.

For professional electrical and low-voltage contractors like Network Drops, preventing scope creep is not only about staying organized; it is essential for protecting profitability and reputation.

Scope creep occurs when additional work is added to a project without approval, proper documentation, or revised payment terms. In low voltage wiring systems such as data cabling, fiber optics, and cleanroom wiring, even minor design changes can significantly affect the overall installation.

Each seemingly “simple” change consumes crew time, disrupts sequencing, and increases material costs. If undocumented, contractors may never get compensated for the additional work.

Scope creep reduces profit margins. A rework rate of 3–5% can wipe out a project’s earnings. It also strains teams, who must re-estimate, reorder materials, and reschedule tasks.

In commercial constructions, low-voltage work is frequently one of the last systems to be designed, which implies that alterations of the details are still continuing at the time of the mobilization of the electrical contractors.

Architects and general contractors may still be finalizing layouts when cabling starts. When device locations, counts, or ceiling designs shift, the low-voltage plan must shift too.

Technology evolves faster than construction timelines. Clients may decide mid-project to switch from CAT5e to CAT6A or opt for fiber-to-desk connections. These changes require new cabling, connectors, and testing methods outside the original plan.

Sometimes clients simply change their minds. “Can you add another access point?” sounds harmless, but it can mean pulling new conduit, ordering new materials, and revisiting the drawings. Without documentation, those changes become free work.

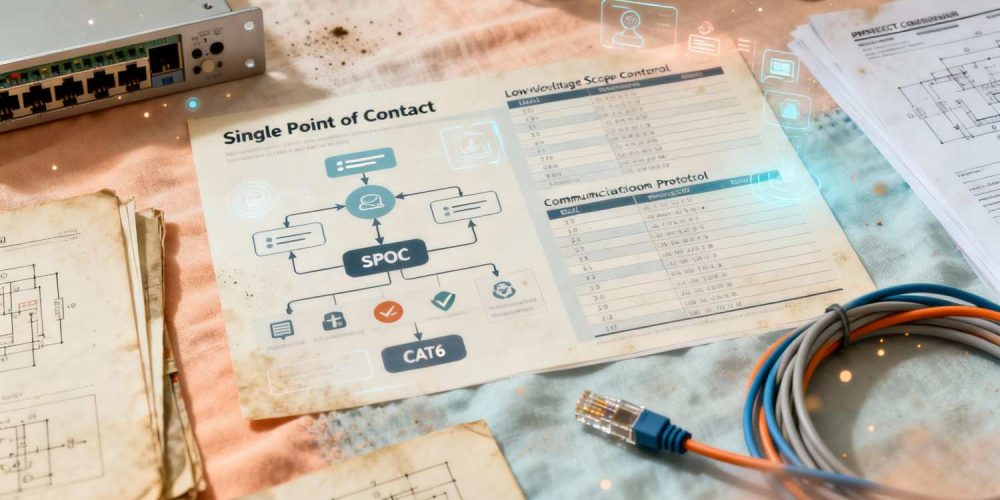

The most important way to prevent changes in the project’s original goals is to establish a clear understanding of the project from the very start. An unambiguous and documented scope eliminates doubts and gives you strong support when clients demand changes.

Clear documentation sets the tone for a smooth project. Your low-voltage scope sheet should outline every key detail: from cable types like Cat6 & CAT6A Cabling, fiber, or coax to device counts, testing standards, and labeling formats. Include information on racks, patch panels, and how labeling should be done. Just as important, clearly state what’s not part of the job, such as AV or security cabling unless specifically included. Defining both deliverables and exclusions upfront prevents confusion and future disputes.

Don’t just ask what your client wants, ask why. Are they upgrading for faster speeds, better safety, or to prepare for future growth? Do they plan to expand their IT setup soon? Understanding their goals helps you design a flexible system that meets today’s needs without adding unnecessary costs or complexity.

Protect yourself contractually. Every agreement should include a clause like:

“Any change in design, materials, or quantities after project start must be documented in a written change order signed by both parties prior to execution.”

This ensures both you and the client agree on how additional work will be priced and approved.

Slight modifications here and there seem unavoidable in any sort of well-planned project. Chaos or control depends upon what and how you handle these modifications.

Change is inevitable but managing it well keeps your project on track. Follow this straightforward process every time:

This consistent workflow ensures clarity, protects your margins, and keeps everyone aligned.

Always re-evaluate materials and labor. Adding 10 CAT6 runs may sound small, but it can require a full additional day of labor and hundreds of dollars in materials. Depending on the site layout, that change could add $1,200–$1,800 to your costs.

Every change order should have a timestamp, signature, and version number. Avoid verbal approvals; those are the leading source of payment disputes.

Many instances of scope creep come from simple miscommunication between clients and field crews.

Only one person, typically the project manager, should communicate official scope updates. Field technicians shouldn’t accept or promise extra work directly to clients.

Give your team clear scripts for handling requests professionally:

“I’ll note that for our project manager. They’ll review and get you an update.”

This keeps your reputation strong while maintaining control over scope changes.

Have brief coordination meetings at key milestones: after rough-in, before termination, and before closeout. Going through the plan and signing scope documents at each stage helps everyone stay aligned and minimizes unexpected issues.

When plans or designs change, manual re-counting of cabling and devices wastes time and introduces errors.

Automated take-off software such as Countfire or Bluebeam Revu helps you re-estimate quickly and accurately when new drawings arrive.

According to Countfire’s estimating insights, automation reduces miscounts and keeps estimates accurate as plans change.

Add clear assumptions to each bid, such as:

“Estimate includes 100 data ports with an average 500 ft run.”

This protects you if the final layout exceeds those quantities.

When a revision adds an equipment room or extra floor, update cable runs, conduit lengths, and labor hours. Regular updates prevent you from absorbing unplanned costs.

Using clear templates and consistent processes keeps projects organized, compliant, and on time. Standardization eliminates communication barriers and guarantees that all team members have the same expectations throughout the entire process.

Get a clear scope of work first. Specify precisely what is included and what is not. Included items can be structured cabling like CAT6 with complete testing, labeling, and certification, along with patch panels, racks, and documentation. Excluded items could be audio/visual wiring, security systems, or PoE lighting if they are not part of the project. Presenting this information early helps avoid confusion once work begins.

Change orders should include the request number and date, a brief description of the change, the impact on cost and time, and the signatures of both contractor and client. This guarantees transparency, safeguards the budget, and avoids disputes.

Include a 5–10% materials allowance on large projects to cover small field adjustments. This minimizes administrative delays for minor changes while protecting your finances.

Creeping of low-voltage scope does not need to be an industry doom and gloom scenario. It is possible for contractors to maintain their projects as forecastable and lucrative by clearly defining the scope, recording changes, employing digital estimating tools, and establishing strict communication limits.

Since 1986, the Network Drops division of Magna5 has partnered with firms in New Jersey and Pennsylvania to design and install high-performance low-voltage networks, such as CAT6, fiber optic, and cleanroom systems, with a focus on long-term reliability.

Want to make your next project bulletproof against scope creep?

Contact Network Drops today for a free scope review and expert consultation.

It’s when added wiring, devices, or cabling work appears after the project starts without updated approval or pricing.

Incomplete designs, unclear communication, or client requests that bypass the official approval process.

Document everything, establish a change-order system, train your crew not to promise extras, and communicate clearly.

Yes. They update counts automatically and help you respond to plan changes in minutes instead of hours.

Because our licensed experts bring decades of experience designing and installing low-voltage systems that stay on time, on budget, and free from scope surprises.

"*" indicates required fields

Scott Fcasni is the driving force behind Magna5’s commercial datacomm cabling division, delivering expert solutions that power reliable, high-performance network infrastructures. With extensive experience in structured cabling and a commitment to precision, Scott ensures that every project—whether for small businesses or large enterprises—meets the highest standards of quality and scalability.